We make treats that brighten your day. What brightens ours is knowing we’re sparking positive change and that we’re looking after every person at every step of making our delicious products. We’re committed to staying Little as we grow. This means a lower carbon footprint, sourcing responsibly and doing business with respect.

Brighter Future is the name of our Sustainability Strategy, and it has three pillars.

Little Moons are manufactured across two factories, in London, in the UK. You can find Little Moons in over 35 countries around the world.

Growth with Integrity

Growth at all costs isn’t an option. Growing the right way matters.

Using B Corp as a guide for embedding sustainability into our business processes, we will make sure we always consider people and planet in our decision making. We will develop guardrails which enable every member of the Little Moons team to feel empowered to make the right call every time.

B Corp certify and grow

Certified B Corps are businesses that are committed to being a force for good by meeting high social and environmental standards. Through a rigorous assessment of 5 core pillars; Environment, Workers, Customers, Community and Governance, companies are verified on their performance.

Little Moons proudly became a B Corp in late 2024. Achieving this certification is testament to the in-roads we’ve made on our sustainability impact so far as a business.

We are using B Corp to guide our business to grow in a way that maintains high sustainability standards. Being a part of the B Corp movement allows us to connect and learn from like-minded businesses who strive to do business better.

To find out more about the B Corp movement, check out the B Corp website.

Movers & Makers

Factory-based employees who make the mochi magic happen

Supporters

Office-based employees who support getting our mochi out into the world for people to enjoy

Educate & Engage

Training is a crucial part of building sustainability awareness and understanding. In 2023, this started with over 200 of our Supporters completing a two-part Sustainability training.

In 2025, we will deliver sustainability training to all Movers & Makers and deliver deep-dive training on carbon and B Corp to our Supporters.

Sustainable Practices

All of our Supporters have a sustainability measure within their objectives, as every individual has a responsibility to act sustainably across the business.

Little Footprint

We know that climate change is one of the greatest challenges we face. We also know that some of our incredible ingredients come from places already grappling with the impacts of climate change.

Near Term Target

30% carbon intensity reduction in Scope 3 by the end of 2030

Long Term Target

Net Zero by 2040 in Scopes 1 & 2

90% carbon intensity reduction in Scope 3 by the end of 2050

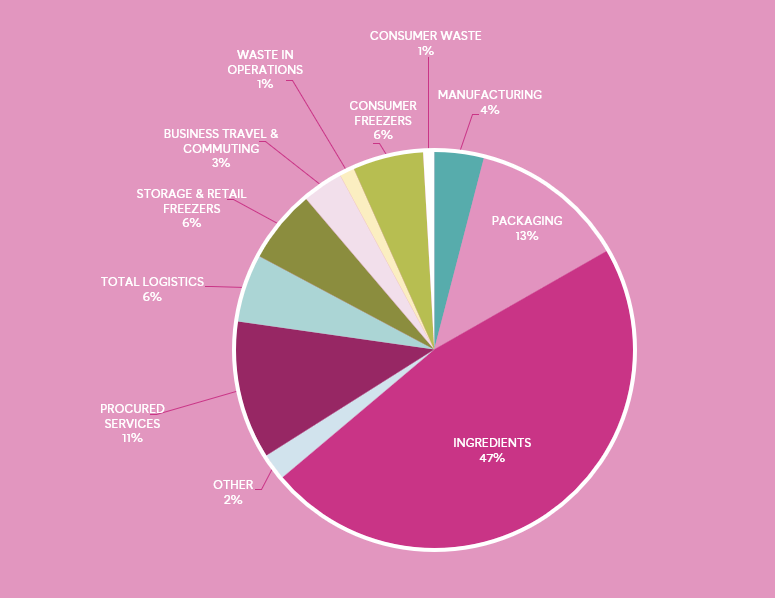

Understanding Our Carbon Footprint

Reducing carbon impact as a business begins with understanding our baseline. Our carbon footprint baseline year is 2022.

Little Moons' carbon intensity is 5.64kg of CO2e per kg of product.

Little Moons' corporate carbon footprint (CCF) is mapped across Scope 1, 2, and 3, which means it's properly measured, from end-to-end. This includes everything from farming our ingredients all the way to our consumers recycling our packaging in their bins at home! This is what makes up Little Moons corporate carbon footprint:

Scope 1: The direct emissions created by Little Moons, for example from using our gas-powered boilers and running the vans we own.

Scope 2: The indirect emissions associated with the energy we purchase, for example the emissions produced to make the electricity we source.

Scope 3: All the indirect emissions associated with the downstream and upstream activities of our business, for example the emissions from farming our ingredients or transporting Little Moons around the world.

Corporate Carbon Footprint

As it stands

Around half of our products are plant-based. According to our friends at Climate Partner who helped us calculate our carbon footprint, nut milk is about 76% less emission intensive than whole dairy milk. In 2023 we reduced our 'Ton-Mile-Revenue' by 22% from the previous year. This is a calculation of our total mileage / total revenue and measn we make more revenue, with less lorries on the road. Result!

Reducing Our Carbon Footprint

After we calculated our baseline, we moved into target setting. We have committed to becoming Net Zero in Scope 1 & 2 by the end of 2040 and reducing our Scope 3 carbon intensity by 90% by the end of 2050.

Whilst we have set our targets, we have not yet signed up to the SBTi (Science-based Target initiative), an organisation who validates decarbonisation targets. Little Moons is a rapidly growing business, and as decarbonisation targets are set from a business’ baseline, we cannot yet confidently commit to an SBTi-aligned reduction pathway for our Scope 3. This is something we will review annually.

Whilst setting future targets is important, the action starts now. Therefore, as a near term target, we aim to reduce the carbon intensity of our Scope 3 by 30% by the end of 2030.

Better Manufacturing

Whilst our carbon footprint is integral to our impact, our environmental impact is broader than this, and tackling this begins with our own manufacturing operations.

We aim to understand our direct water footprint by the end of 2025, before building a reduction plan.

Our food waste is recycled across our manufacturing sites and is sent to anaerobic digestion facilities to generate biofuel.

We source renewable electricity for all our primary manufacturing sites and offices, which comes from a UK wind source.

Our Packaging

Packaging is necessary to keep our delicious mochi safe, but there is more we can do to ensure our packaging materials are made from recycled and certified content, and that they can be widely recycled. We are holding ourselves accountable to developing internal sustainability packaging guidelines in 2024, to ensure we better ourselves in the future.

Our retail 6-pack frozen mochi packaging is made up of 3 parts: our plastic trays, which contain 50% post-consumer recycled plastic (RPET), are made by Kingsmoor in the UK, and are recyclable alongside plastic recycling waste.

Our carton boxes are made by Qualvis in the UK, using 100% FSC sources of British trees, which are recyclable alongside paper or cardboard waste.

Our protective film is printed by Coveris in the UK and is made of PET plastic and must be disposed of through general waste.

Our products are transported to our customers in corrugated cardboard which is also 100% recyclable.

We are proud to say that 96% of our packaging is recyclable. Just remember to follow the 3 R's...

Remove the plastic film (put that into the general rubbish bin).

Use leftover washing up water to rinse your plastic before recycling.

Make sure all components are clean and dry when you dispose of them. Pop the tray and cardboard sleeve into your recycling bin.

Positive Sourcing

Our ingredients are fundamental to our business, so building positive relationships with our ingredient suppliers is critical. Sustainability, security of supply and quality all go hand in hand.

Near Term Target

Responsibly sourced key ingredients by 2026

Long Term Target

100% responsibly sourced ingredients by 2030

Portfolio Ingredient Strategy

We source ingredients from all around the world to make our delicious flavours. 100% of our ingredients will be responsibly sourced by 2030, with our key ingredients of dairy, rice and cocoa, meeting this standard by 2026.

"Responsibly sourced" can be a spectrum and we are committed to being transparent on what this means for us. Later this year, once we have onboarded our suppliers to this programme, we will outline our definition in more detail.

We are Sedex Buyer members and use Sedex to assess our social and environmental risk and build traceability through our supply chain.

Building Positive Supplier Relationships

Having strong working relationships with our suppliers is crucial to understanding our impact and creating positive change.

We work with a range of different suppliers to source our ingredients, for example:

The cream in our products comes from Meadow, and the cream in our products comes from Pattemores, both of which source and process our dairy from the UK only.

All of our delicious fruits are sourced and processed by a business we've been working with for many years. This includes Alphonso Mango from India which is used in our Alphonso Mango Mochi Ice Cream and the Italian Lemons which go into our Yuzu and Lemon Mochi Ice Cream.

Future

Sustainability is not something that can be 'completed', and therefore our strategy is constantly evolving in line with research, innovation, policies and regulations. Keep an eye on this page as we continue to better ourselves, for both people and planet.

Back to the top

Back to the top